Cost Reduction Examples

CASE1 Reduced waste oil and waste solution

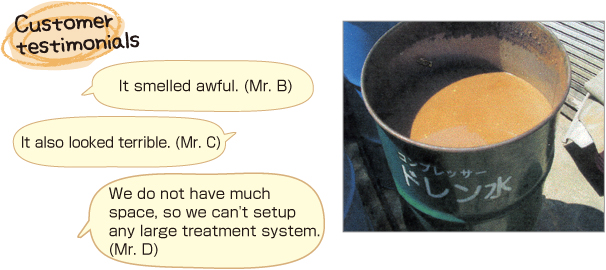

Customer Concerns

Company A (automobile part manufacturer)

- To reduce the amount of industrial waste product to

treat and its treatment costs - (1) To reduce the costs for treating compressor drain

waste solution

(2) To be able directly to drain waste solution from the

drain

Present state

Drain waste solution was collected in a pale, and then switched to a drum.

This was then outsourced to a treatment specialist for treatment.

- Company A compressor equipment Annual waste-solution treatment costs

- 15 kw: (0.2 L/h × 20 h) x 6 units = 24 L

- 22 kw: (4 L/h × 20 h) x 2 units = 160 L

- 37 kw: (5 L/h × 8 h) x 2 units = 80 L

- Monthly discharge amount: 264 L x 22 days = 5,808 L

- Monthly treatment costs: 5,800 L x ¥47 = ¥272,600

- Annual treatment costs: 58,000 L x ¥47 = ¥2,726,000

Our proposal

Reduce treatment costs 1/10 by using a new

waste-solution treatment system

Proposed use of a new treatment system that is lightweight, compact and does

not use electricity.

Collects floating oil within the system so it can be directly discharged.

Drain waste solution treatment costs can be lowered to 1/10 of existing

expenditures.

- Implemented assessment tests before delivery